Material Lead Times & Sourcing: Navigating the New Normal in Network Deployment

In today’s economic climate of inflation, geopolitical tensions and fluctuating demand, material availability has become as critical as engineering excellence. As telecom networking infrastructure expands to meet connectivity demands, contractors, integrators and carriers face a new reality where sourcing constraints and extended lead times directly shape project execution.

Whether it’s fiber optic cable, hardened enclosures or active electronics, securing materials at the right time is now a strategic imperative. Success depends not only on design and labor, but on the ability to anticipate, adapt and execute amid supply chain volatility.

A Lingering Legacy

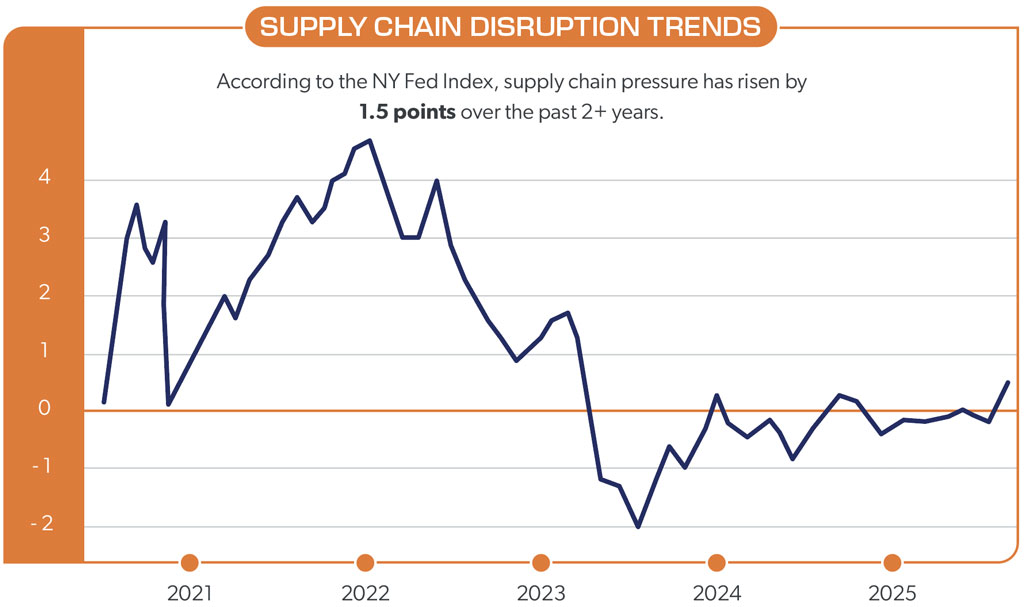

Despite post-pandemic recovery efforts, supply chain disruptions continue rippling through the telecom sector. Structural issues combined with economic volatility have extended lead times, complicated logistics and constrained material availability.

Ongoing challenges include:

Raw material shortages: Scarcity of copper, polyethylene, specialty glass and rare earth elements has limited production capacity

Manufacturing backlogs: High-demand components like hardened connectors, ONTs, splitters

and power systems remain constrained due to overloaded factoriesLogistics bottlenecks: Port congestion, rail slowdowns and transportation delays continue disrupting delivery timelines, worsened by labor shortages and fuel cost fluctuations

Custom or specialized materials now take three to six months or more to procure. These delays create cascading effects across engineering, permitting and construction, forcing project teams to adjust sequencing and resourcing in real time.

Delays Beyond Delivery

Material shortages create wide-ranging impacts on project execution and profitability, especially in today’s uncertain economy.

Key effects include:

Permitting expiration: Late material arrivals can cause approved construction windows to lapse, forcing reapplication and schedule delays

Crew inefficiencies: Idle time from missing parts leads to rescheduling, rework or temporary labor reassignment, driving up costs

Financial strain: For fixed-bid or milestone-driven projects, cash flow disruption occurs through late payments and escalating carrying costs

In a high interest rate environment, the financial implications of project delays are more acute. This has elevated material planning from a background function to a critical path activity.

From Reactive to Proactive

Network builders are adopting sophisticated procurement and inventory strategies designed to reduce risk while aligning with construction timelines and economic constraints.

Leading practices include:

Long-range demand planning: Forecasting material needs 12 to 18 months ahead based on project pipelines, permitting milestones and funding cycles

Multi-vendor sourcing: Diversifying supplier relationships to avoid single points of failure, especially for long-lead or mission-critical components

Early Material Release (EMR): Securing key materials before final design approval to lock in availability and buffer against future disruption

Distributors such as GCG Telecom Solutions offer Vendor Managed Inventory (VMI) and just-in-time field replenishment to smooth deployment and reduce warehousing burdens on contractors.

Streamlining the Buildout

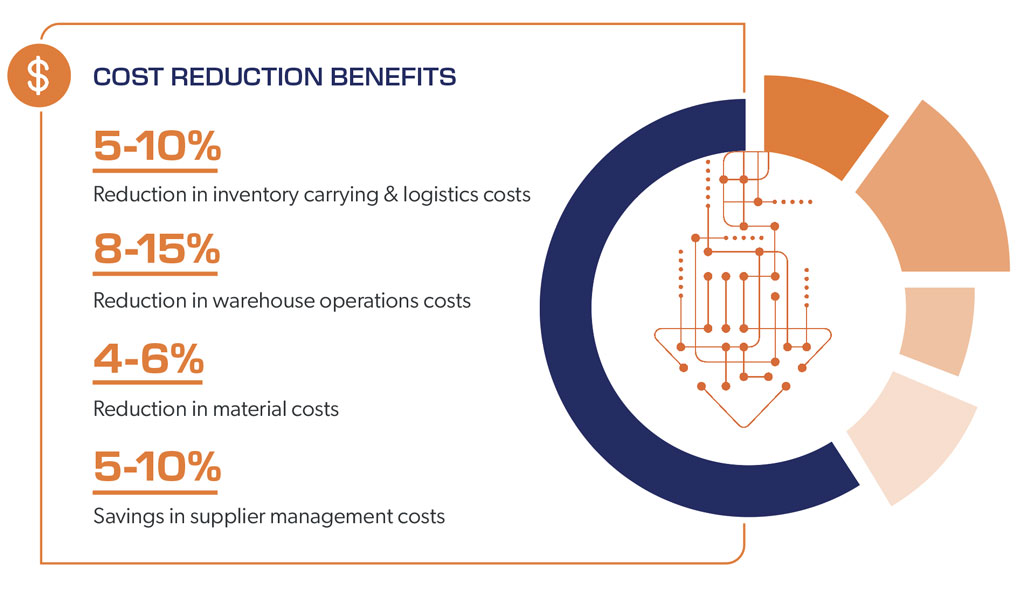

Standardization represents one of the most effective strategies to reduce procurement complexity through unified, repeatable designs and pre-kitted solutions that minimize variability across builds.

Benefits of standardization and kitting:

Accelerated procurement: Fewer custom orders and more predictable lead times

Improved field efficiency: Job-ready kits reduce prep time and installation errors

Reduced mismatch risk: Standard BOMs lower the chance of incompatible or missing components, avoiding costly change orders

This approach fosters better coordination between engineering, purchasing and field operations — essential for executing large-scale builds in uncertain economic conditions.

Procurement as a Competitive Edge

With telecom demand projected to grow and government funding tied to aggressive deployment targets, material sourcing will remain a defining challenge. Economic uncertainty will only magnify

the need for smarter procurement.

Organizations that align supply chain strategy with project velocity through advanced forecasting, standardization, supplier collaboration and real-time flexibility will be best equipped to deliver on time, at scale and within budget. In this new era of network deployment, procurement is your strategic lever for competitive advantage. GCG Telecom Solutions can help.