Inventory Management and Logistics: Streamlining Field Readiness in a High-Velocity Market

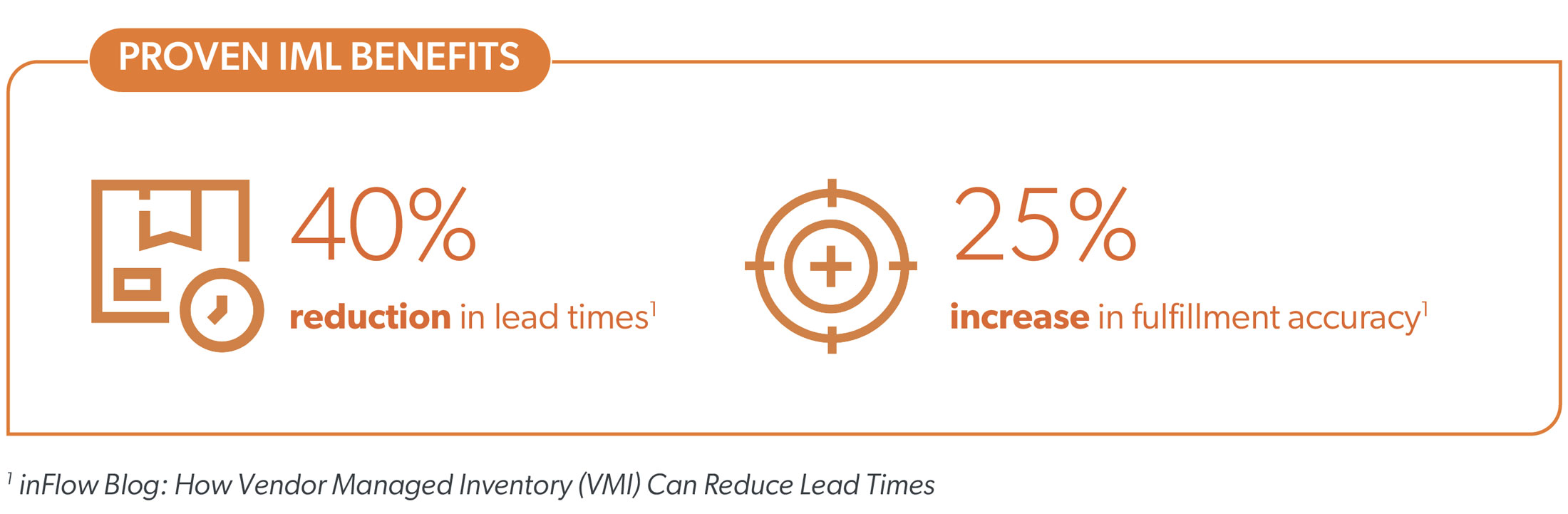

As telecom deployment cycles accelerate and supply chain volatility persists, Inventory Management & Logistics (IML) has emerged as a critical strategy for ensuring material availability where and when it’s needed. For carriers, integrators and contractors, IML offers a proven path to reduce field friction, improve cash flow and maintain deployment velocity without overwhelming internal logistics teams.

What is IML?

Inventory Management & Logistics is a supply chain management strategy through which suppliers take responsibility for managing and replenishing inventory levels at customer locations. Instead of telecom operators placing purchase orders, vendors monitor usage and stock levels, making restocking decisions based on predefined service levels and demand forecasts.

IML in the Telecom Context

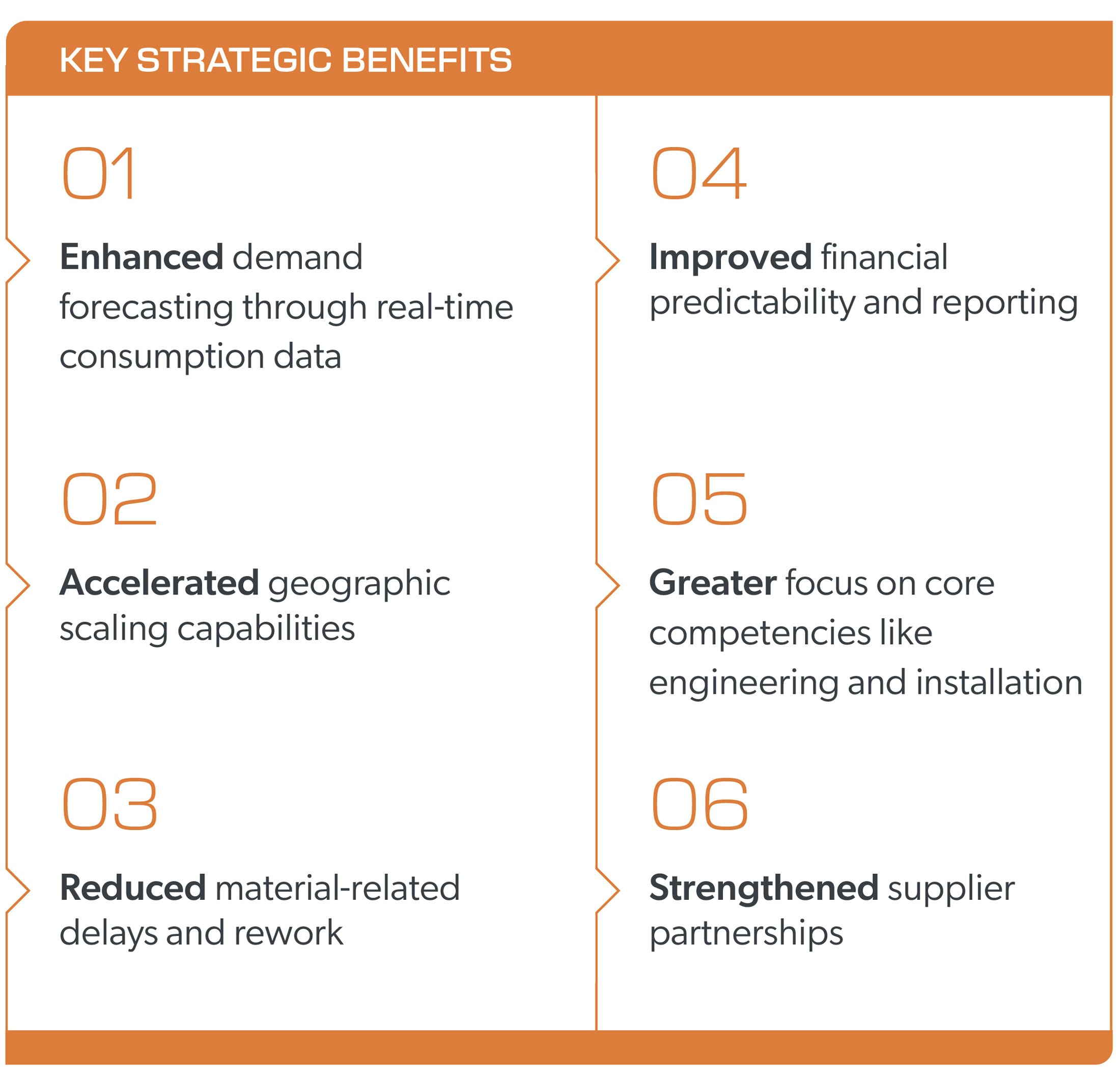

In telecom applications, distributors or suppliers maintain inventory levels using real-time consumption data, project forecasts and replenishment triggers. This approach shifts inventory planning and stockout management from contractors and integrators to a collaborative, data-driven partnership.

With geographically distributed networks and frequent infrastructure upgrades, telecom operators often face a choice between overstocking (capital inefficiencies) or stockouts (delayed rollouts

and maintenance).

Common telecom IML applications include:

Stocking fiber, conduit, enclosures and hardware at regional hubs or jobsite trailers

Replenishing kits or assemblies based on usage rates

Providing inventory visibility through dashboards or APIs

IML allows telecom providers to leverage equipment vendors and distributors who forecast and replenish inventory using real-time data from warehouses, field service hubs and project pipelines. This ensures critical infrastructure components are available when and where needed.

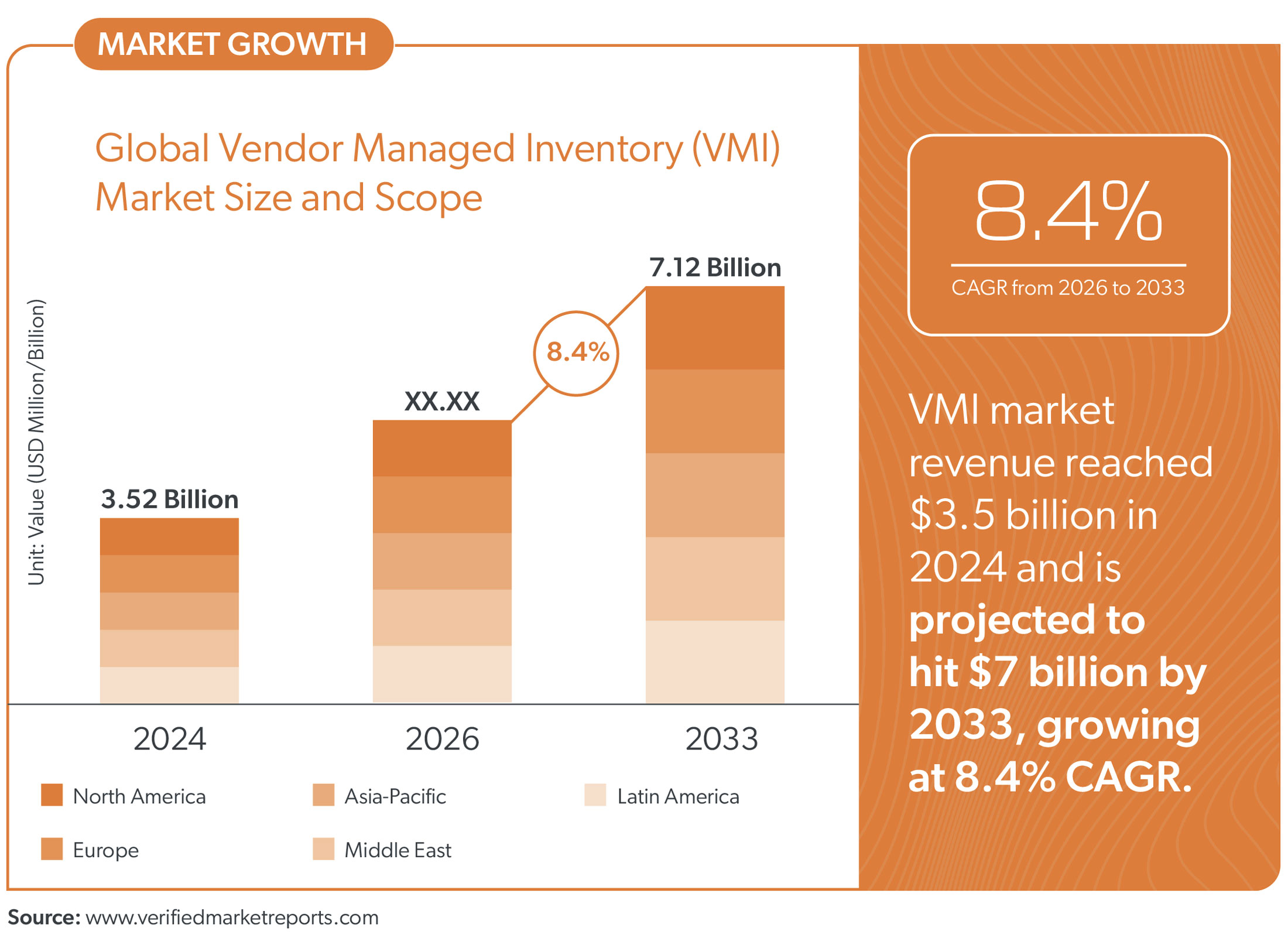

Why IML Matters Now

Telecom networks face constant pressure to evolve, supporting 5G rollouts, fiber expansion, edge computing and IoT proliferation. In this environment, inventory shortages or supply chain misalignment can derail major capital projects and damage customer satisfaction.

With BEAD and other funding programs driving aggressive build schedules, material delays carry unprecedented costs. IML mitigates these risks by:

Reducing lead time variability

Minimizing over-ordering and excess inventory

Improving field crew productivity through consistent material availability

Freeing working capital by shifting inventory ownership until consumption

IML also enables just-in-time delivery models, particularly valuable in urban or remote deployments with limited storage capacity.

Keys to IML Success

Effective Inventory Management & Logistics implementation requires alignment across operations, procurement and field teams. Best practices include:

Clear consumption tracking through barcode scanning or IoT-enabled bins

Collaborative forecasting between project managers and suppliers

Defined service levels and replenishment thresholds

System integration with ERP or project management platforms for real-time visibility

Leading distributors, such as GCG Telecom Solutions, often bundle IML with kitting, staging and logistics services, creating comprehensive material management solutions.

Strategic Advantages for Integrators and Contractors

Inventory Management & Logistics delivers substantial strategic value beyond supply chain efficiency. In a competitive market where speed, reliability and scale determine contract wins and deployment success, IML becomes a competitive differentiator.

Looking Ahead

As networks become increasingly distributed and deployment timelines compress, IML will play

an expanding role in enabling agile, scalable operations. Contractors and integrators who embrace this model and build strong supplier partnerships will be better positioned to meet tomorrow’s telecom networking infrastructure demands.

The time is now for telecom leaders to rethink their supply chain strategies and integrate IML as a cornerstone of operational excellence.